In today’s highly competitive electronics industry, efficiency and precision are critical. Manufacturers around the globe are constantly searching for ways to improve productivity while maintaining the highest standards of quality. The smt pick and place machine by NECTEC addresses these challenges head-on. Engineered with cutting-edge technology and precision-driven mechanics, NECTEC’s SMT pick and place machine is the ultimate solution for companies seeking reliability, speed, and scalability in their surface-mount technology operations.

Understanding the Role of an SMT Pick and Place Machine

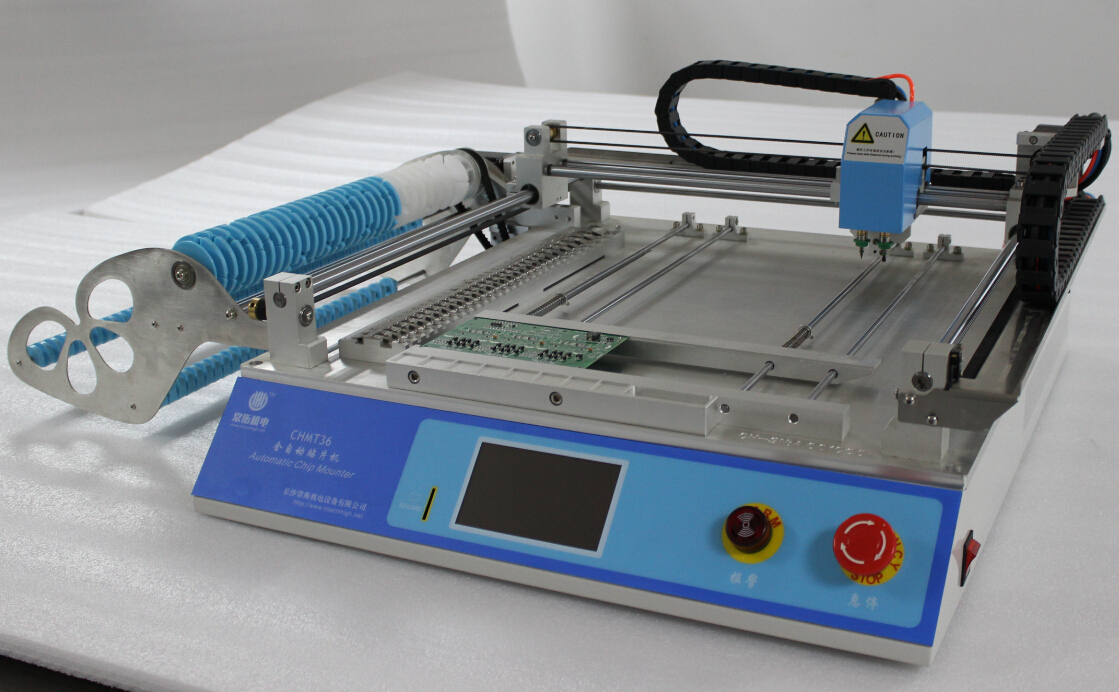

An SMT pick and place machine is a vital component in the electronics manufacturing process. It is responsible for accurately placing surface-mount components onto printed circuit boards (PCBs) during assembly. These machines are commonly used in the production of smartphones, computers, automotive electronics, and countless other devices. A high-quality SMT pick and place machine ensures not only placement accuracy but also contributes significantly to reducing production errors and operational downtime.

NECTEC has developed a state-of-the-art SMT pick and place machine that meets and exceeds the needs of modern manufacturing. With advanced automation, high-speed processing, and the flexibility to handle various component types and sizes, NECTEC’s solution is at the forefront of electronic assembly technology.

Key Features of NECTEC’s SMT Pick and Place Machine

High-Speed Component Placement

One of the defining features of NECTEC’s SMT pick and place machine is its high-speed operation. Engineered for rapid processing, this machine significantly reduces cycle times while maintaining consistent accuracy. This feature is essential for high-volume manufacturing environments where time-to-market plays a pivotal role.

Precision and Accuracy

Accuracy is paramount in SMT assembly. NECTEC’s pick and place machine utilizes vision-assisted alignment systems to ensure components are placed with micrometer precision. This level of accuracy minimizes soldering issues and enhances the overall reliability of the assembled PCBs.

Flexibility and Component Compatibility

The electronics manufacturing landscape is constantly evolving, with new components and packages being introduced regularly. NECTEC’s SMT pick and place machine is designed to accommodate a wide range of component sizes, shapes, and package types. This flexibility allows manufacturers to stay agile and adapt to changing design requirements without needing to invest in new machinery.

Scalable Architecture

Whether you’re operating a small assembly line or a high-throughput production facility, NECTEC’s SMT pick and place machine is designed to scale with your business. Its modular design enables easy expansion and integration with other production line systems, allowing seamless upgrades as your manufacturing needs grow.

Intelligent Software Integration

The software that powers the NECTEC SMT pick and place machine is just as impressive as its hardware. With intelligent programming, real-time diagnostics, and production analytics, operators gain complete control and visibility over the entire assembly process. This integration ensures consistent quality and facilitates preventive maintenance, thereby reducing downtime.

Why Choose NECTEC?

Choosing the right SMT pick and place machine can make a significant difference in manufacturing efficiency and product quality. NECTEC stands out in the industry for several compelling reasons.

Proven Reliability

NECTEC has built a reputation for producing highly reliable machines that operate consistently under demanding conditions. Their SMT pick and place machines undergo rigorous quality testing to ensure long-term performance in high-volume settings.

Local Support and Service

Customer service is a key differentiator for NECTEC. With a dedicated support team and widespread service network, clients receive timely assistance for installation, training, troubleshooting, and maintenance. This local support minimizes disruptions and ensures optimal machine utilization.

Customization Options

Recognizing that every manufacturing environment is unique, NECTEC offers customization options to tailor the SMT pick and place machine to specific production requirements. From feeder configurations to placement head options, clients can build a machine that perfectly aligns with their operational goals.

Applications Across Industries

The versatility of NECTEC’s SMT pick and place machine makes it suitable for a wide range of industries. Whether you’re manufacturing consumer electronics, automotive components, medical devices, or industrial control systems, this machine delivers unmatched performance and precision. Its adaptability makes it an ideal choice for contract manufacturers handling a variety of product types.

Enhancing Production Efficiency

Efficiency is more than just speed; it also involves reducing waste, optimizing resources, and minimizing human error. NECTEC’s SMT pick and place machine is designed with these principles in mind. Features like automatic component verification, real-time error detection, and predictive maintenance contribute to a leaner, more cost-effective production process.

Environmental and Energy Considerations

In addition to performance, NECTEC emphasizes sustainability. Their SMT pick and place machine is built to operate with energy efficiency in mind. Lower power consumption, minimal material waste, and compliance with environmental standards make it an eco-friendly choice for forward-thinking manufacturers.

Future-Ready Technology

NECTEC is continuously investing in research and development to enhance the capabilities of their machines. Their SMT pick and place machine is future-ready, supporting advanced component technologies and integration with Industry 4.0 systems. This future-proofing ensures that manufacturers investing in NECTEC technology today are well-positioned to meet the demands of tomorrow.

ROI and Cost-Effectiveness

While the upfront investment in high-quality SMT equipment may seem significant, NECTEC’s SMT pick and place machine delivers excellent return on investment. Faster production times, reduced rework rates, and lower operational costs contribute to substantial long-term savings. For companies looking to boost profitability without compromising quality, this machine is a wise investment.

Customer Testimonials

Many clients have praised NECTEC’s SMT pick and place machines for their performance and reliability. Manufacturers report improvements in yield rates, reduced downtime, and enhanced product consistency after switching to NECTEC systems. These real-world success stories demonstrate the value and impact of choosing a high-performance machine from a trusted provider.

Integration and Automation

Modern manufacturing demands seamless integration across various systems. NECTEC’s SMT pick and place machine is designed to interface smoothly with solder paste printers, reflow ovens, and automated optical inspection systems. This interoperability allows for a fully automated and synchronized production line, reducing manual intervention and maximizing throughput.

NECTEC’s Commitment to Innovation

NECTEC is more than a machine manufacturer. The organization is committed to innovation and technological advancement. With a focus on continuous improvement and customer-centric design, NECTEC remains a leader in the field of surface-mount technology. Their SMT pick and place machine embodies this spirit of innovation, offering a solution that is not only effective today but ready for tomorrow’s challenges.

Conclusion

For electronics manufacturers seeking a reliable, fast, and scalable solution, NECTEC’s SMT pick and place machine stands out as a top-tier choice. With its advanced features, robust build quality, and exceptional performance, it delivers unmatched value in modern PCB assembly. Investing in this machine is a strategic move toward greater efficiency, higher output, and superior product quality.

Click here to return to the homepage and unlock more content.

Explore NECTEC’s solutions today and take your manufacturing to the next level with confidence.

FAQs

What is an SMT pick and place machine used for?

An SMT pick and place machine is used in electronics manufacturing to accurately place surface-mount components onto printed circuit boards during the assembly process.

What makes NECTEC’s SMT pick and place machine stand out?

NECTEC’s SMT pick and place machine is known for its speed, precision, scalability, and intelligent software integration, making it ideal for a wide range of industrial applications.

Can NECTEC’s SMT pick and place machine handle small production runs?

Yes, NECTEC’s machine is designed to be scalable and flexible, making it suitable for both small batch and high-volume production environments.