Understanding Injection Molding Prototypes

Definition and Overview of Injection Molding

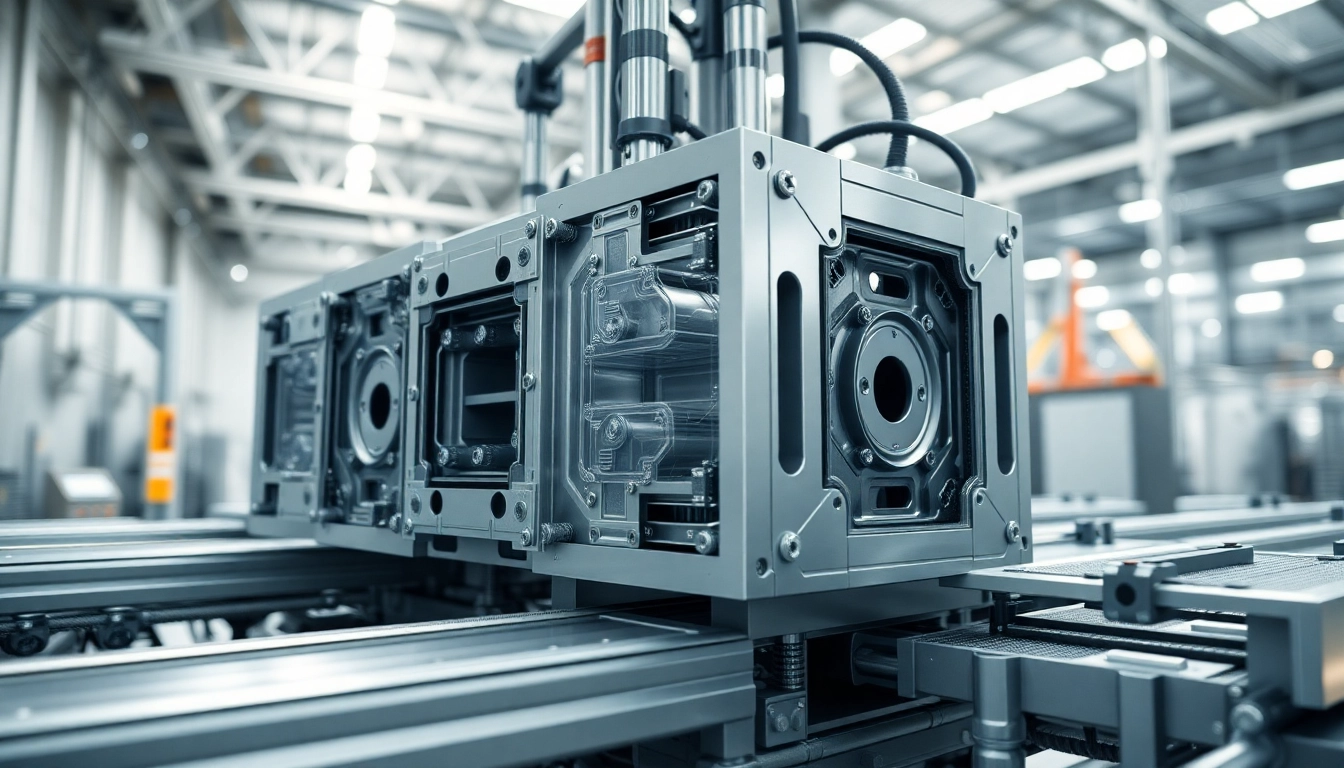

Injection molding is a manufacturing process that creates parts by injecting molten material into a mold. This technique is commonly used for producing plastic parts but can also be applied to metals and glass. It involves several steps, starting with design and prototyping, moving to tooling, and finally, mass production. The process is favored for its ability to produce complex shapes with high precision and repeatability. As a critical early stage in product development, injection molding prototypes play an essential role in validating designs, materials, and functionality before full-scale production begins.

Benefits of Using Injection Molding Prototypes

The advantages of using injection molding prototypes are numerous and significant. Firstly, they allow designers and engineers to assess the physical dimensions and functional aspects of their designs before committing to costly mass production. This can prevent expensive design alterations when issues are discovered late in the production process. Furthermore, injection molding prototypes can closely replicate the final product’s mechanical properties, testing the performance of materials used for production.

Injection molding also supports rapid development. Using advanced technologies such as CAD software and rapid tooling, designers can create prototypes quickly. Thanks to precise manufacturing capabilities, injection molded prototypes can be produced in low to medium volumes, offering flexibility and speed without sacrificing quality. Finally, because prototypes can be created in the actual production material, testing can be more accurate, leading to better product validation and fewer unforeseen issues during later production stages.

Common Applications in Various Industries

Injection molding prototypes serve diverse industries, including automotive, consumer products, medical devices, and electronics. In the automotive sector, prototypes enable the testing of complex assemblies and parts that require stringent tolerances. For consumer products, prototypes help validate ergonomics, aesthetics, and functionality before going to market.

In the medical field, injection molding prototypes are crucial for testing components such as housings for medical devices, surgical instruments, and disposables, where high precision and safety standards are mandatory. Furthermore, the electronics sector benefits significantly, utilizing prototypes for enclosures and connectors, ensuring that performance meets the required specifications without unexpected malfunctions.

The Prototype Development Process

Initial Design Considerations

When starting the prototype development process, several design considerations must be addressed. It is essential to define the part’s purpose, its design specifications, and the expected performance characteristics. A focus on manufacturability can also save time and costs down the line, ensuring that the design aligns well with the injection molding process.

The considerations also extend to material selection, as different plastics or composites may interact differently during the molding process or yield varying properties in the finished product. Ultimately, the choice of design will influence the tooling strategy, cost, lead times, and product performance.

Prototyping Tools and Technologies

Prototyping tools and technologies have evolved considerably, providing manufacturers and designers with advanced capabilities. CAD software allows designers to create and modify designs efficiently, while simulation software can analyze stress points, thermal properties, and fluid dynamics to optimize the prototype before fabrication.

Rapid tooling technologies such as soft tooling and aluminum molds can expedite the creation process, significantly reducing lead times compared to traditional steel tooling. Additionally, advancements in 3D printing can aid in developing initial design iterations, serving as a cost-effective means to visualize and test concepts before moving to injection molding.

Steps to Create an Injection Molding Prototype

The creation of an injection molding prototype generally proceeds through several key steps:

- Conceptual Design: Develop initial sketches or CAD models of the part.

- Material Selection: Choose the appropriate resins or materials that mimic the production environment.

- Tooling Design: Design the molds required for injection molding, considering design specificities and production requirements.

- Prototype Fabrication: Utilize rapid tooling methods to fabricate the injection mold and produce the prototype parts.

- Testing and Validation: Conduct a series of tests on the prototype to ensure it meets design specifications and functional criteria.

- Feedback and Iteration: Gather feedback from testing and make necessary adjustments to the design before finalizing the production mold.

Cost Considerations for Injection Molding Prototypes

Factors Influencing Prototype Costs

Several factors influence the costs associated with injection molding prototypes. The complexity of the part design plays a significant role; intricate designs that require detailed molds will generally cost more to produce. Material choice is another major factor—specialty materials or those with specific mechanical properties can raise costs compared to more common materials.

The size of the prototype also influences costs. Larger prototypes require more material and longer cycle times in the molding machine, thereby increasing costs. Furthermore, the type of tooling used can greatly affect expenses, with soft tools being less expensive than traditional steel tools but offering limited usability in a production context.

Budgeting for Prototyping Projects

When budgeting for injection molding prototyping projects, it’s important to anticipate not just the direct costs but also any unexpected expenses that may arise due to design modifications or material changes. This can involve setting aside a contingency fund as part of the overall budget to cover potential overruns. It can also be beneficial to evaluate multiple quotes from different suppliers and manufacturers to ensure the most cost-effective approach is taken without compromising quality.

Additionally, creating a phased budget that outlines changes as milestones can help in maintaining control over project spending and timelines, ensuring that costs remain in check throughout the prototyping process.

Cost-Effective Strategies for Small to Medium Enterprises

For small and medium enterprises (SMEs), it is imperative to adopt cost-effective strategies when managing injection molding prototypes. One approach is to leverage partnerships with prototyping companies that specialize in small-batch production runs, allowing SMEs to meet their prototyping needs without the significant capital investment required to set up their tooling.

Implementing design for manufacturability (DFM) practices early in the design phase can also reduce costs. Ensuring that the design can be efficiently produced using available technologies minimizes changes later in the process and leads to smoother production runs. Moreover, considering a staged prototyping approach can help in testing hypotheses and gathering data before investing in full-scale production.

Comparison with Other Prototyping Methods

Comparing Injection Molding Prototypes vs. 3D Printing

While both injection molding and 3D printing aim to create prototypes, they serve different purposes and are suited for various applications. 3D printing is ideal for rapid prototyping and small-scale applications, providing flexibility and faster turnaround times. It enables designers to quickly test ideas and generate feedback.

On the other hand, injection molding prototypes yield higher fidelity replicas of the final design. They showcase how a product will perform with the actual production materials, while 3D printing usually utilizes different materials or methods that might not accurately reflect the final product’s properties.

The choice depends largely on the project stage, budget, and requirements for performance testing, with injection molding preferred for parts requiring stringent tolerances or that will eventually be mass-produced.

Speed and Efficiency of Injection Molding

Injection molding is often perceived as a slower technique for initial prototype development due to setup times associated with creating molds. However, once the molds are created, the speed and efficiency of the injection process are unmatched, allowing for the rapid production of multiple parts in a short time frame.

For projects requiring numerous iterations but ultimately transitioning to larger production runs, injection molding can be considerably time-efficient. Additionally, modern technologies have been developed to streamline the mold-making process, contributing to quicker prototyping and reduced time to market.

When to Choose Injection Molding Over Traditional Methods

Choosing injection molding over traditional methods should be based on specific project requirements. If high precision, material performance, and production readiness are paramount, injection molding is typically the preferred approach. It is particularly advantageous for parts that will undergo rigorous testing and validation processes before full-scale manufacturing.

Conversely, for projects that focus on rapid conceptual validation rather than final specifications, alternative methods such as 3D printing may provide the agility and flexibility necessary. Understanding unique project parameters can help in selecting the most appropriate prototyping method.

Case Studies and Success Stories

Notable Examples of Successful Projects

Certain success stories stand out in the realm of injection molding prototypes. Consider the automotive industry, where a well-known manufacturer utilized injection molded prototypes to develop a new line of interior components. By leveraging rapid prototyping techniques, they were able to iterate on designs quickly, leading to significant reductions in time-to-market.

Another example is found in the medical device field. A company developing a new surgical tool utilized injection molding prototypes to not only test functionality but also validate compliance with regulatory standards. This preemptive validation streamlining ultimately facilitated successful certification far quicker than if testing was conducted only on the finished product.

Lessons Learned from Injection Molding Prototyping

Each successful project offers valuable lessons. One crucial takeaway is the importance of early stakeholder engagement. Including stakeholders during the design and testing phases ensures that all functional and user-centered requirements are addressed from the outset, minimizing iterative changes later in the development process.

Moreover, clear communication with manufacturing partners can mitigate potential issues. Laying a solid foundation for collaboration can lead to smoother transitions from prototyping to full-scale production.

Future Trends in Prototype Development

As technology continues to advance, several trends are emerging in the realm of prototype development. The integration of artificial intelligence and machine learning in the design phase promises to enhance predictive analytics, allowing engineers to optimize designs even before prototypes are created. This can lead to faster problem resolution and more innovative solutions.

Additionally, the emergence of hybrid manufacturing techniques, where traditional methods like injection molding are combined with additive technologies such as 3D printing, is revolutionizing the speed and flexibility of prototype development. This trend enables designers to quickly validate concepts while also producing highly functional prototypes harnessing the benefits of multiple manufacturing processes.