Introduction to Plastic Parts Manufacturing

In today’s industrial landscape, the manufacture of plastic parts serves not just as a means of production but as a cornerstone of several industries, ranging from automotive to electronics and consumer goods. This evolution reflects not only advancements in technology but also the increasing demand for high-quality, cost-effective, and sustainable solutions that meet the needs of businesses and consumers alike.

Understanding the Manufacture of Plastic Parts

The manufacture of plastic parts encompasses a range of processes that transform raw materials into functional components through various techniques. The most common methods include injection molding, extrusion, blow molding, and thermoforming. Each technique is suited for different applications, based on the materials used, the complexity of the design, and the volume of production required. From high-precision automotive components to flexible packaging solutions, understanding these processes is crucial for managing any manufacturing project.

Key Terminology and Concepts in Plastic Manufacturing

Before delving into the manufacturing processes themselves, it is essential to familiarize ourselves with basic terminologies. Key concepts such as thermoplastics and thermosetting plastics, mold design, and tight tolerances play a significant role in determining the success of manufacturing endeavors. Thermoplastics can be remelted and reshaped, whereas thermosetting plastics undergo a chemical change that hardens them permanently. Understanding these differences aids manufacturers in selecting the right materials for specific applications, ensuring durability and performance.

The Importance of Quality in Production

Quality assurance is paramount in the manufacture of plastic parts. Implementing stringent quality control measures throughout the production process can significantly reduce defects, enhance product durability, and improve customer satisfaction. Employing techniques such as Six Sigma or Total Quality Management (TQM), organizations can identify areas of inefficiency and minimize variability in production. These methodologies not only enhance the quality of products but also contribute to overall cost savings within the manufacturing cycle.

Main Manufacturing Processes for Plastic Parts

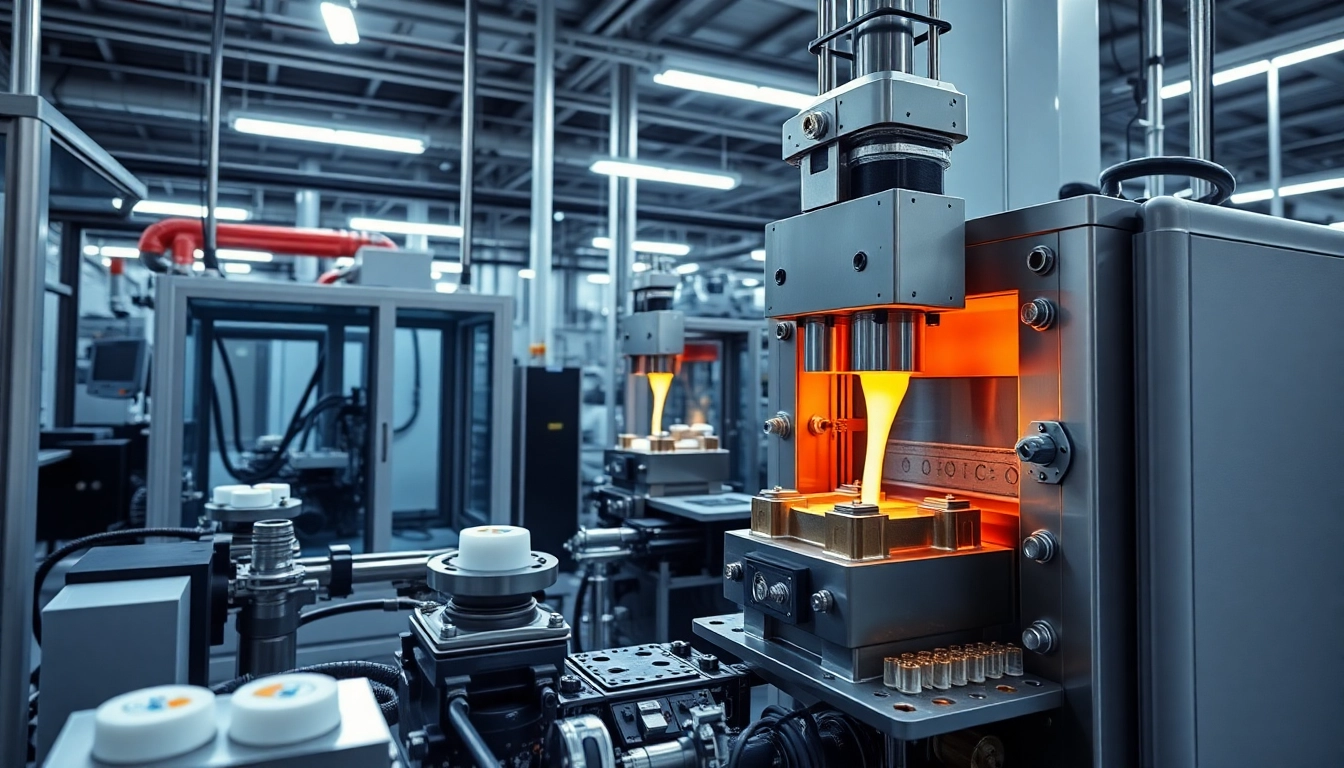

Injection Molding: A Deep Dive into the Process

Injection molding is one of the most widely used techniques for the manufacture of plastic parts and can yield complex shapes with high precision. The process involves injecting molten thermoplastic materials into a mold under high pressure, allowing for the creation of parts that exhibit excellent dimensional accuracy and surface finish. Key factors in this process include the type of plastic used, the design of the mold, and the cycle time, all of which influence the overall efficiency and cost of production.

Exploring Alternative Methods: Extrusion and Blow Molding

Extrusion is another common method where melted plastic is pushed through a die to create continuous shapes, such as tubes or sheets, which are then cut to length. Blow molding, on the other hand, is utilized primarily for manufacturing hollow objects. In this method, air is blown into a heated plastic tube, expanding it against the mold. Both techniques allow for the creation of lightweight structures and have applications in industries ranging from packaging to automotive manufacturing.

Comparative Analysis of Different Techniques

When choosing the right manufacturing process for plastic parts, a comparative analysis is essential. Injection molding tends to be favored for higher production volumes due to its speed and precision, while extrusion may be more suitable for continuous manufacturing processes. Blow molding excels in producing hollow structures economically. A thorough understanding of the advantages and limitations of each process allows manufacturers to optimize production methods tailored to specific project requirements.

Material Selection for Plastic Parts

Common Plastics Used in Manufacturing

The selection of materials is a critical factor in the manufacture of plastic parts. Commonly used plastics include polyethylene (PE), polypropylene (PP), and polystyrene (PS). Each material has distinct properties that make it suitable for certain applications. For instance, polyethylene is known for its chemical resistance and is widely used in packaging, while polypropylene offers superior rigidity and is often found in automotive parts.

Choosing the Right Material for Your Project

Choosing the appropriate material for a specific project requires careful consideration of factors such as strength, flexibility, environmental conditions, and cost. Conducting tests and simulations can provide valuable insights into material performance under various stress and environmental scenarios. Collaborating with suppliers and engineers can lead to informed decisions that enhance the quality and sustainability of the final products.

Environmental Considerations in Material Choice

Sustainability is increasingly becoming a priority in the plastics industry. When selecting materials, manufacturers must consider the environmental impact of their choices. Biodegradable plastics, recycled materials, and those produced through sustainable practices are becoming more available. Implementing these options not only contributes to reducing the carbon footprint of production processes but also enhances brand reputation among environmentally conscious consumers.

Best Practices in Plastic Parts Manufacturing

Strategies for Reducing Waste and Enhancing Efficiency

In an effort to improve operational efficiency, manufacturers are adopting strategies designed to minimize waste. Techniques such as lean manufacturing and just-in-time (JIT) production focus on reducing excess material usage and streamlining production processes. Continuous monitoring and process optimization can lead to significant cost savings while maintaining product quality.

Maintaining Consistency in Quality Control

Maintaining quality throughout the production process is essential for customer satisfaction and regulatory compliance. Utilizing automated inspection technologies along with statistical process control (SPC) can ensure products meet defined specifications and trigger corrective actions when deviations occur. Regular training and certification of staff involved in quality assurance are also vital to sustaining high standards.

Utilizing Technology to Streamline Production

Technology advancement is reshaping the plastics manufacturing industry. The integration of IoT (Internet of Things) devices facilitates real-time monitoring of production processes, enabling manufacturers to gather data that can be used for predictive maintenance and optimized scheduling. Advanced software simulations also allow for virtual testing of designs and production scenarios, minimizing costly prototypes and accelerating time-to-market.

Future Trends in Plastic Parts Manufacturing

Innovations Shaping the Future of the Industry

The future of plastic parts manufacturing will be significantly influenced by innovations in materials and processes. The rise of advanced composites, hybrid materials, and smart plastics promises to expand the range of applications and functionalities of plastic parts. Increased automation in manufacturing and the implementation of AI and machine learning can potentially revolutionize production efficiency and quality management.

Impact of Sustainability on Manufacturing Practices

As global awareness of environmental issues grows, sustainability will play an increasingly crucial role in manufacturing practices. Companies are integrating sustainable practices into their operations, ranging from materials sourcing to waste management. This includes the use of recycled materials, energy-efficient production methods, and the implementation of circular economy principles to reduce waste. Manufacturers who prioritize sustainability are likely to gain a competitive advantage and customer loyalty.

Preparing for the Challenges Ahead in Manufacturing

While the future holds promise, it also presents challenges that manufacturers must be prepared to tackle. These challenges include navigating regulatory changes, ensuring workforce adaptability amid technological advancements, and maintaining cost-effective operations in a dynamic market. Proactive planning, investment in employee training, and continuous evaluation of market trends will be essential strategies for thriving in the future landscape of plastic parts manufacturing.