In modern manufacturing, precision and reliability are more than buzzwords—they’re the backbone of productivity and profitability. One of the most critical components in assembly and industrial production lines is the Fastener Machine. For decades, UTA has stood as a trusted name in this field, developing machines that don’t just fasten components—they enhance entire production ecosystems.

Today, we explore how a reliable fastener machine not only fixes errors but also delivers consistent power and performance, making it an indispensable asset across wiring, automotive, and fastener industries.

The Role of a Fastener Machine in Manufacturing

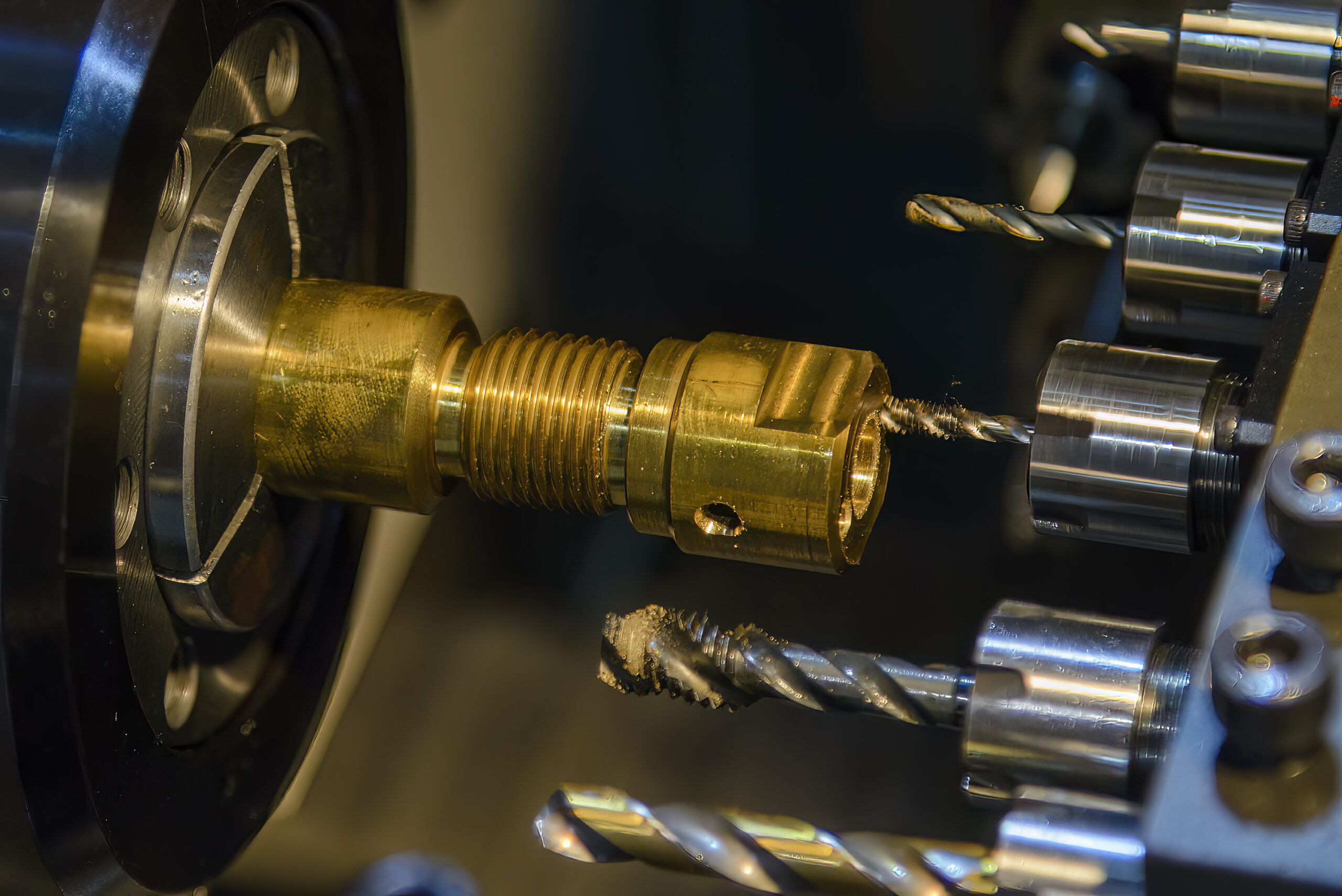

Fastener machines are used to assemble bolts, screws, washers, and other hardware into products at scale. Whether it’s assembling car parts, electrical systems, or consumer electronics, fastener machines ensure that components are secured with precision. The speed and accuracy of these machines drastically reduce human error and accelerate throughput, which is vital for large-scale operations.

But a machine is only as good as its consistency. That’s why UTA continues to innovate by engineering fastener machines that deliver powerful, error-free results, every time.

Why Reliability in Fastener Machines Matters

Reliability is not just about fewer breakdowns—it’s about long-term consistency, reduced downtime, and high-quality output. When your fastener machine is reliable, you eliminate:

- Incorrect placements that compromise structural integrity

- Inconsistent torque that leads to product failures

- Frequent jams that slow down the production line

- Misfeeds that waste materials and time

UTA’s fastener machines are designed with robust quality assurance systems, ensuring minimal faults and maximum uptime.

Common Fastening Errors and How UTA Machines Fix Them

1. Misalignment

One of the most frequent issues in automated fastening is misalignment. UTA machines utilize smart sensors and real-time alignment correction to ensure every component is placed precisely.

2. Torque Inconsistencies

Without accurate torque control, fasteners may be either under-tightened or over-tightened, leading to weak joints or damaged parts. UTA’s advanced torque monitoring systems eliminate this risk by maintaining uniform torque output.

3. Component Jams

Older machines suffer frequent jams due to inefficient feeding systems. UTA machines feature optimized feeder tracks and vibration-reducing mechanisms that prevent parts from clogging the system.

4. Speed-Powered Errors

High-speed operations often lead to compromised accuracy. UTA strikes a perfect balance with programmable speed controls that adapt to different tasks without sacrificing precision.

The Power Behind UTA Fastener Machines

UTA’s fastener machines are not only reliable—they’re powerful. Here’s what sets them apart:

- Heavy-Duty Construction: Made from industrial-grade materials to withstand high-volume usage.

- High-Speed Output: Processes thousands of components per hour without quality loss.

- Modular Flexibility: Easily adapt the system for different fasteners or project needs.

- Energy Efficiency: Smart power management reduces electricity consumption by up to 20%.

From small-scale operations to major automotive assembly lines, UTA’s machines bring the power manufacturers need to stay competitive.

Industry Applications of UTA’s Fastener Machines

Fastener machines from UTA are used across multiple industries, including:

- Automotive: For securing components in engines, suspensions, and chassis assemblies.

- Electronics: For placing tiny screws in delicate devices with micrometric accuracy.

- Aerospace: Where reliability and precision are non-negotiable due to safety regulations.

- Home Appliances: Ensuring tight fittings in washing machines, refrigerators, and ovens.

Each machine is customized for industry-specific demands, making UTA a go-to choice for engineers and production managers worldwide.

How UTA Ensures Fastener Machine Reliability

1. Rigorous Testing

Before a UTA fastener machine leaves the facility, it undergoes a comprehensive set of tests including vibration analysis, torque testing, and long-run performance assessments.

2. Smart Diagnostics

UTA machines come with self-diagnosing software that alerts users to potential issues before they cause failures. This predictive maintenance feature extends machine life and prevents costly downtimes.

3. Lifetime Support

UTA offers lifelong technical support and maintenance packages to keep your machines running like new—even after years of heavy use.

Future-Ready Innovation

In 2025 and beyond, UTA is investing in machine learning and AI-integrated fastener machines that can learn from patterns, improve over time, and adapt autonomously to material or design changes. This next generation of machines will push productivity to new heights while maintaining UTA’s commitment to error-free performance.

Frequently Asked Questions (FAQ)

1. What makes UTA’s fastener machines more reliable than competitors?

UTA machines are built with precision engineering, advanced sensors, and self-diagnostic systems. Each machine is tested under extreme conditions to ensure long-term durability and minimal maintenance needs.

2. Can a UTA fastener machine be customized for different projects?

Yes. UTA offers modular systems that can be configured to handle a wide variety of fasteners, sizes, and production requirements. Customization is a key strength of the UTA engineering team.

3. How does UTA prevent fastener machine jams?

UTA uses optimized feeder tracks, vibration-dampening structures, and real-time monitoring to prevent misfeeds and jams. The result is smoother, faster, and more reliable operation.

Final Thoughts: Invest in Performance, Invest in UTA

When errors aren’t an option, and performance is non-negotiable, a fastener machine from UTA is your smartest investment. UTA’s machines are built not just to function—but to lead. With built-in intelligence, robust construction, and years of proven reliability, these machines are a game-changer for any manufacturing floor. Your journey starts at our homepage—check it out today.

Don’t let inefficiencies hold your operations back. Trust UTA. Trust power, precision, and perfection.

Ready to upgrade your production line? Contact UTA today and discover the next level of fastening excellence.